How to Choose a Motor Soft Starter?

Step 1 — Match the Rated Voltage

Step 2 — Check the Rated Current

A Simple Guide for Beginners

Class 10 – Light Loads

Class 10B – Standard Industrial Loads

Class 20 – Heavy or High Inertia Loads

Class 30 – Severe Duty Loads

Recommended Motor - Soft Starter Matching Table

Soft Starter (kW)

Class 10 Motor (kW)

Class 10B Motor (kW)

Class 20 Motor (kW)

Class 30 Motor (kW)

Choosing the Soft Starter Type

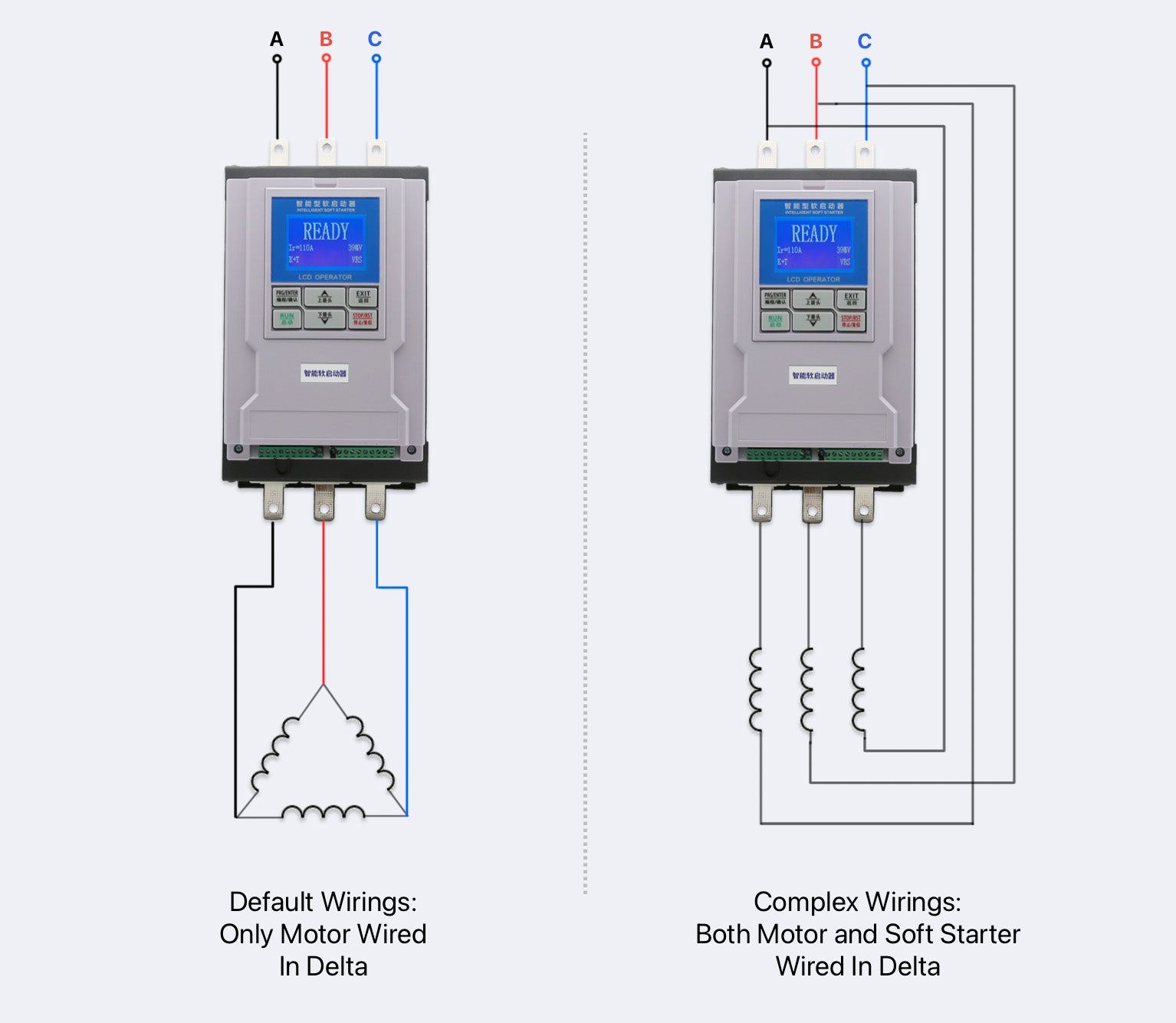

Default Wiring Configurations