Features

Control Modes

Start Modes

Stop Modes

Protection Functions

Ambient Conditions

Keypad Operation

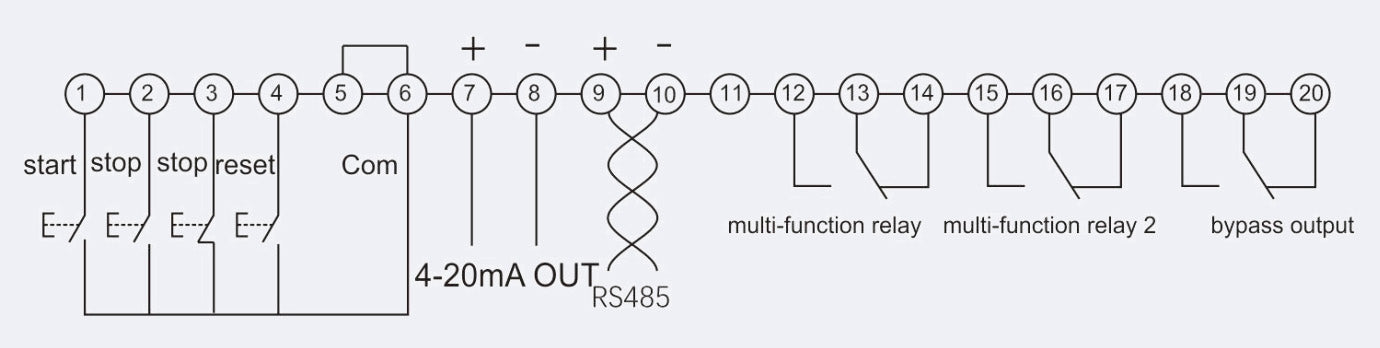

Terminal Functions

Selection Guide

| 380V SKUs | Class 10 Motor (kW) | Class 10B Motor (kW) | Class 20 Motor (kW) | Class 30 Motor (kW) |

|---|---|---|---|---|

| ASF6K-5P5 | 4.3 | 4.2 | 3.7 | 3 |

| ASF6K-7P5 | 5.9 | 5.7 | 5.1 | 4.1 |

| ASF6K-11 | 8.6 | 8.4 | 7.5 | 6.1 |

| ASF6K-15 | 11.7 | 11.4 | 10.2 | 8.3 |

| ASF6K-18P5 | 14.4 | 14.1 | 12.6 | 10.2 |

| ASF6K-22 | 17.2 | 16.7 | 15 | 12.1 |

| ASF6K-30 | 23.4 | 22.8 | 20.4 | 16.5 |

| ASF6K-37 | 28.9 | 28.1 | 25.2 | 20.4 |

| ASF6K-45 | 35.1 | 34.2 | 30.6 | 24.8 |

| ASF6K-55 | 42.9 | 41.8 | 37.4 | 30.3 |

| ASF6K-75 | 58.5 | 57 | 51 | 41.3 |

| ASF6K-90 | 70.2 | 68.4 | 61.2 | 49.5 |

| ASF6K-115 | 89.7 | 87.4 | 78.2 | 63.3 |

| ASF6K-132 | 103 | 100.3 | 89.8 | 72.6 |

| ASF6K-160 | 124.8 | 121.6 | 108.8 | 88 |

| ASF6K-185 | 144.3 | 140.6 | 125.8 | 101.8 |

| ASF6K-200 | 156 | 152 | 136 | 110.8 |

| ASF6K-220 | 171.6 | 167.2 | 149.6 | 121 |

| ASF6K-250 | 195 | 190 | 170 | 137.5 |

| ASF6K-280 | 218.4 | 212.8 | 190.4 | 154 |

| ASF6K-320 | 249.6 | 243.2 | 217.6 | 176 |

| ASF6K-350 | 273 | 266 | 238 | 192.5 |

| ASF6K-400 | 312 | 304 | 272 | 220 |

| ASF6K-450 | 351 | 342 | 306 | 247.5 |

Class 10 – Light Loads

Class 10B – Standard Industrial Loads

Class 20 – Heavy or High Inertia Loads

Class 30 – Severe Duty Loads

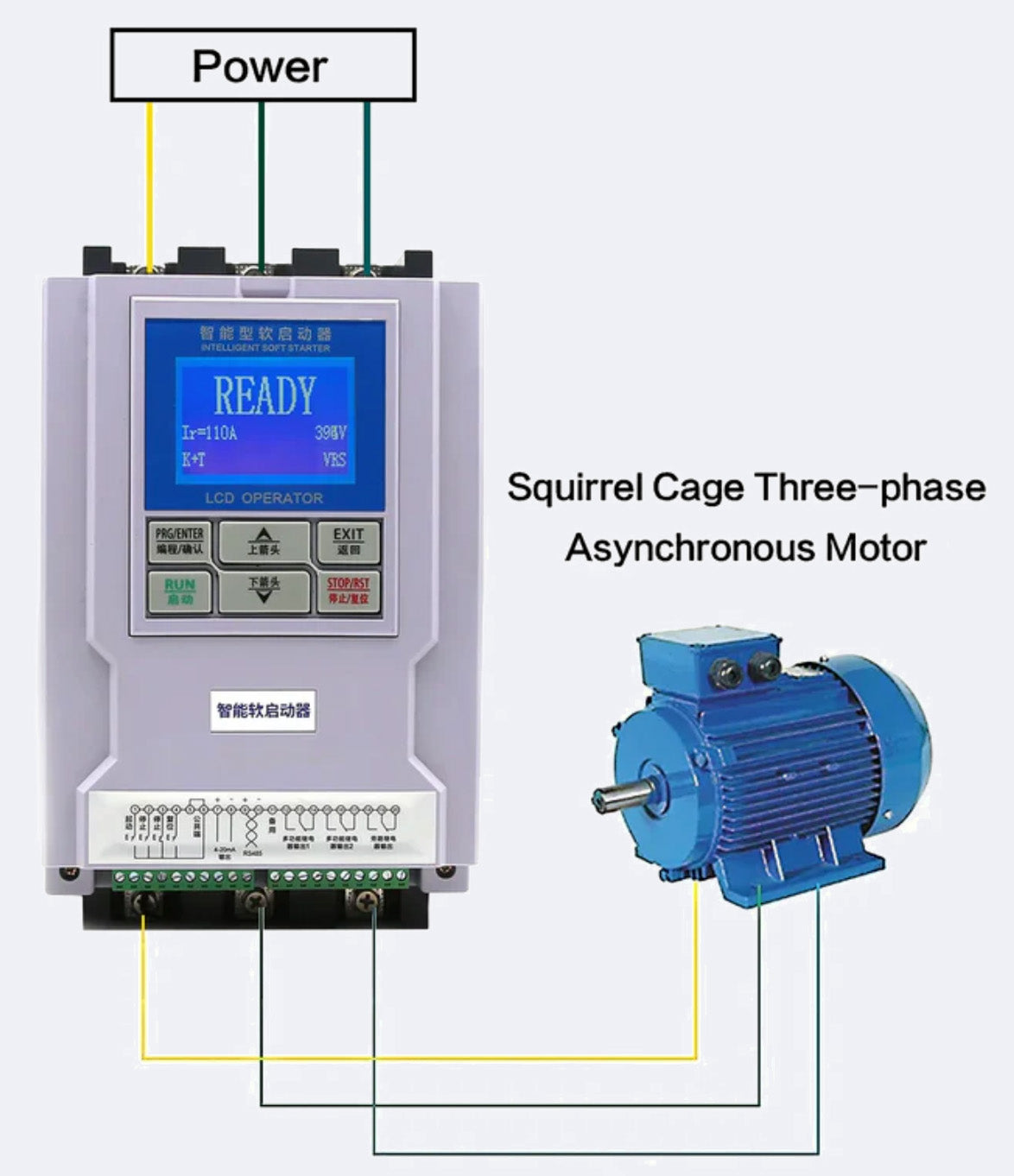

Mains Wirings